ISO 9001:2000

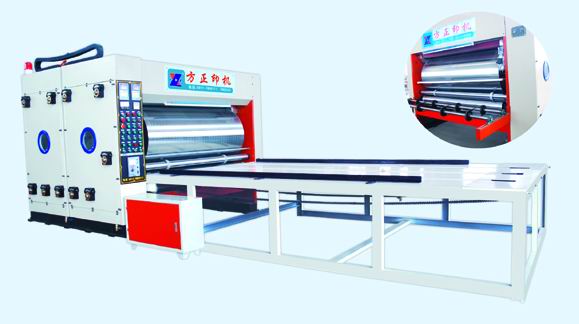

YF2500 Series of Flexo Ink Corrugated Cardboard Printing Pressing Slicing Machine

Product ID: 84414000

Send Inquiry

YF2500 Series of Flexo Ink Corrugated Cardboard Printing Pressing Slicing Machine

Function and Characteristics

1 Paper-feeding unit adopts get-together, chain type to feed paper by hand..

2 Each machine unit adopts moving by electricity, pneumatic lock tight..

3 It adopts the planet type gear structure. The phase adjustment is fast and precisely. Clockwise and anti-clockwise 360 degree phase adjustment while operating and pausing.

4 Each space adjustment can be displayed digitally on the scale panel. It can be adjusted by hand.

5 The auto-rolling rubber roller can prevent water ink drying, when stopping.

6 Adopting helical gear transmission. All the gears are made by high-frequency quenching.

7 Gears lubrications adopt sprinkled circulation. It can minimize noise and increase gears service life. At the same time, it can also improve the precision of the process printing.

8 With electric counter, it can control printing numbers rightly.

9 Adopting pneumatic dividing pump for auto-transmit water ink.

10 It can be set up with paper pressing line equipment.

Name of Parameter Unit Specification

YF2500*1700 YF2500*1900

Max. size of feeding paper mm 2500*1700 2500*1900

Min. size of feeding paper mm 600 600

Max. printing area mm2 2480*1400 2480*1600

Adaptable thickness of cardboard mm 2-11 2-11

Thickness of standard printing plank mm 7.2 7.2

Printing roller axle-oriented regulating mm ±10 ±10

Max. production speed Pieces/min 65 65

Precision of process printing (double/three/four color) mm ±0.5/0.75/1.0 ±0.5/0.75/1.0

Main electrical power (single/double/three/four color) kw 4/5.5/7.5/11 4/5.5/7.5/11

General power (single/double/three/four color) kw 5.85/8.45/11.55/16.15 5.85/8.45/11.55/16.15

Total weight (single/double/three/four color) kg 4150/7300/10450/13600 4500/8000/11500/15000

Function and Characteristics

1 Paper-feeding unit adopts get-together, chain type to feed paper by hand..

2 Each machine unit adopts moving by electricity, pneumatic lock tight..

3 It adopts the planet type gear structure. The phase adjustment is fast and precisely. Clockwise and anti-clockwise 360 degree phase adjustment while operating and pausing.

4 Each space adjustment can be displayed digitally on the scale panel. It can be adjusted by hand.

5 The auto-rolling rubber roller can prevent water ink drying, when stopping.

6 Adopting helical gear transmission. All the gears are made by high-frequency quenching.

7 Gears lubrications adopt sprinkled circulation. It can minimize noise and increase gears service life. At the same time, it can also improve the precision of the process printing.

8 With electric counter, it can control printing numbers rightly.

9 Adopting pneumatic dividing pump for auto-transmit water ink.

10 It can be set up with paper pressing line equipment.

Name of Parameter Unit Specification

YF2500*1700 YF2500*1900

Max. size of feeding paper mm 2500*1700 2500*1900

Min. size of feeding paper mm 600 600

Max. printing area mm2 2480*1400 2480*1600

Adaptable thickness of cardboard mm 2-11 2-11

Thickness of standard printing plank mm 7.2 7.2

Printing roller axle-oriented regulating mm ±10 ±10

Max. production speed Pieces/min 65 65

Precision of process printing (double/three/four color) mm ±0.5/0.75/1.0 ±0.5/0.75/1.0

Main electrical power (single/double/three/four color) kw 4/5.5/7.5/11 4/5.5/7.5/11

General power (single/double/three/four color) kw 5.85/8.45/11.55/16.15 5.85/8.45/11.55/16.15

Total weight (single/double/three/four color) kg 4150/7300/10450/13600 4500/8000/11500/15000

Certificate

- ISO9001:2000

Main Products

Angle, hinges, handle